Advanced Rotary Table Engineering for Demanding Applications #

Key Features #

- Preloaded Barrel Cam Mechanism: Virtually eliminates backlash, ensuring high positioning accuracy.

- Rolling Friction Transmission: Extends operational life and enhances reliability.

- Steel Transmission Elements: Offers greater rigidity and superior resistance to eccentric loads compared to copper components.

- Double Action Brake System: Pneumatic or hydraulic mechanism guarantees complete unclamping for safe operation.

- External Solenoid Valve & Pressure Switch: Protects internal electrical components from moisture, reducing maintenance needs.

- Absolute Motor Integration: No need for zero return at startup, streamlining setup and operation.

Technical Specifications #

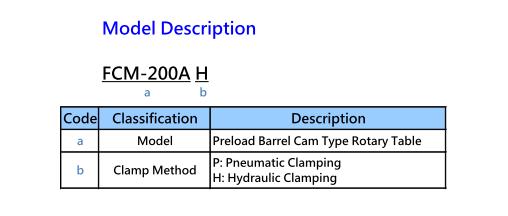

| Specification | FCM-200AP | FCM-200AH |

|---|---|---|

| Use Method | Vertical | Vertical |

| Clamp Method | Pneumatic 5kg/cm² | Hydraulic 35kg/cm² |

| Faceplate Dimension | Ø200mm | Ø200mm |

| Spindle Through Hole | Ø40mm | Ø40mm |

| Faceplate Centre Hole | Ø95mmH7 | Ø95mmH7 |

| Centre Height | 160mm | 160mm |

| Faceplate T-slot Width | 12mmH7 | 12mmH7 |

| Position Key | 18mmh7 | 18mmh7 |

| Absolute Servo Motor | FANUC α4i/β8i, MELDAS HF-104S, Yaskawa SGM7G-09, Siemens 1FK-7060-****-1RG1 | Same as FCM-200AP |

| Reduction Ratio | 1/60 | 1/60 |

| Min. Increment Unit | 0.001° | 0.001° |

| Indexing Accuracy | ±15 (Arc.Sec.) | ±15 (Arc.Sec.) |

| Repeat Accuracy | 10 (Arc.Sec.) | 10 (Arc.Sec.) |

| Clamp Force | 30kgf-m | 144kgf-m |

| Max. RPM (3 sec) | 50rpm@motor3000rpm | 50rpm@motor3000rpm |

| Max. Workpiece Capacity | 80kg (vertical) / 160kg (with tailstock) | Same as FCM-200AP |

| Cam Torque (Continuous/Max) | 210Nm@10rpm / 458Nm | 210Nm@10rpm / 458Nm |

| Net Weight (w/o motor, w/ faceplate) | 76kg | 81kg |

Note: Data applies within the faceplate diameter. For workpieces exceeding this, ensure the maximum inertia value is not surpassed.

Load Capacities #

- Balanced Load (No Tailstock): 80kg, D: Ø200mm, L: 260mm

- Balanced Load (With Tailstock): 160kg, D: Ø200mm, L: 700mm

- Balanced Load (Manual Tailstock): 100kg, D: Ø200mm, L: 700mm

- Eccentric Load (With Tailstock): Eccentric Load = l x W, W: 2.4kg-m

Only one of the three conditions (weight, rotation diameter, length) can be satisfied at maximum load.

Customer Preparation Requirements #

- Hydraulic unit with at least one circuit (DC24V/2B2 solenoid valve)

- Machine equipped with fourth axis function, absolute motor, and amplifier

- Conduit cable (length as required by machine)

- Two oil pipes (length as required by machine)

Standard Accessories #

- Pressure switch with 5m cable

- Three bolt sets and T-blocks (compatible with position key 18mm; T-slot pitch 100 and 125mm)

- Cable seat (conduit cables provided by customer)

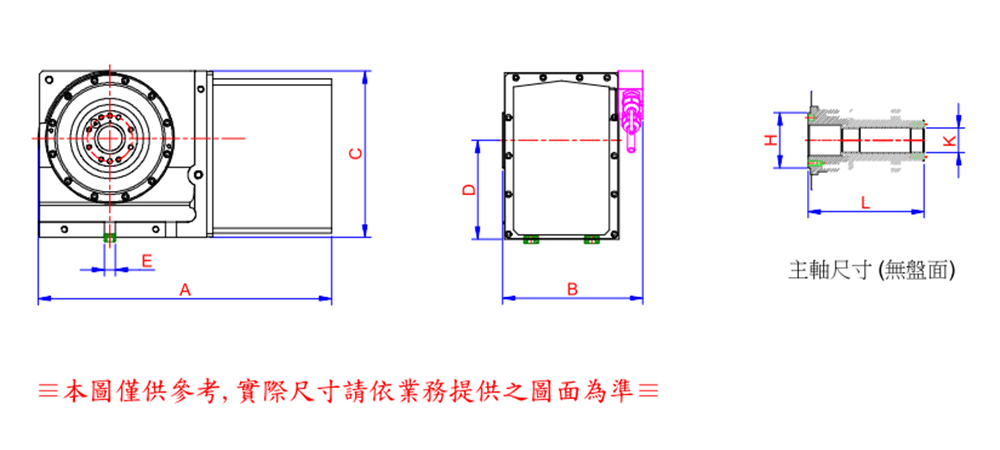

Dimensional Outline (Unit: mm) #

| Model | Total Width (A) | Total Thickness (B) | Total Height (C) | Centre Height (D) | Spindle Through Hole (K) | Plate Outer Diameter (H) | Spindle Length (L) | Screw Pitch, Slot Width (E) |

|---|---|---|---|---|---|---|---|---|

| FCM-200A (No faceplate) | 482 | 231 | 270 | 160 | Ø40 | Ø90 | 190 | 200, 18 |

Contact Information #

- Company: TOPSDISK CO., LTD.

- Address: 1f, No. 220, Shenlin S. Rd. Daya Dist, Taichung City, Taiwan, R.O.C

- Phone: 886-4-25682975

- Fax: 886-4-25681016

- Email: sales@topsdisk.com

For more details, visit the official product page or explore the full product catalog.