Understanding NC Rotary Tables: Types, Features, and Options #

NC rotary tables are essential components in modern machining, enabling precise positioning and multi-axis movement for complex workpieces. At TOPSDISK, we offer a diverse selection of 4th-axis and 5th-axis rotary tables, also known as dual-axis NC rotary tables, designed to meet a variety of manufacturing needs. Below, we detail the main categories, features, and product options available.

Classification of Rotary Tables #

Our rotary tables can be categorized based on installation method, transmission mechanism, clamping system, and size.

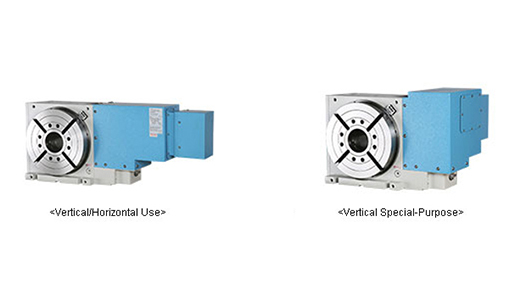

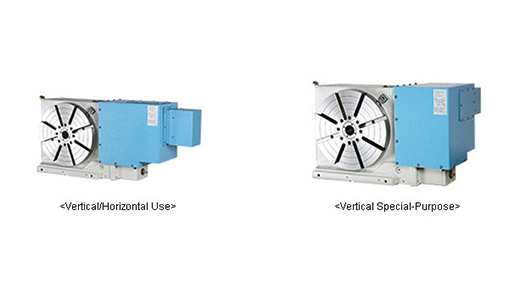

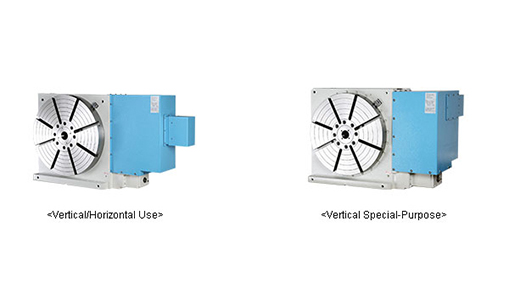

Installation Methods #

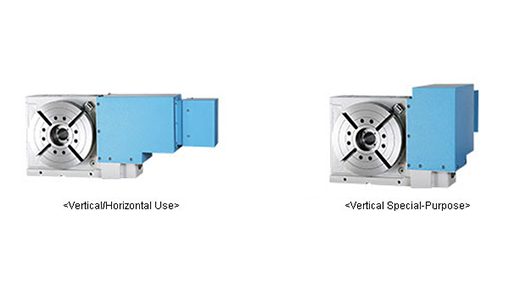

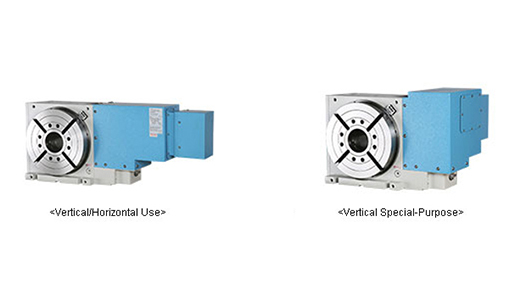

- Vertical Rotary Table: Installed upright, this table rotates on a horizontal plane and can be lifted vertically. This configuration keeps the workpiece stable and allows for flexible height adjustments, enhancing machining efficiency.

- Horizontal Rotary Table: Designed for rotation on a horizontal plane, this type is ideal for positioning workpieces at various angles, making it suitable for multi-angle or multi-face processing machines.

Transmission Methods #

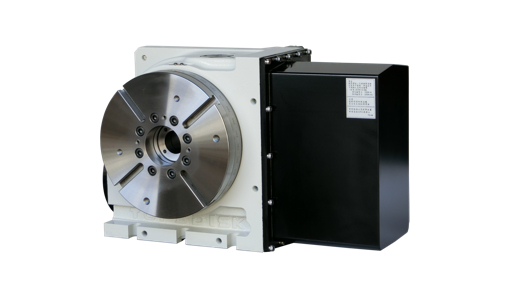

- Direct Drive Rotary Table: Utilizes direct drive technology, eliminating reducers, gearboxes, and pulleys. This results in faster acceleration/deceleration, reduced transmission error, and higher motion stability. Direct drive tables are ideal for high-precision applications but are more costly to manufacture.

- Worm Gear Rotary Table: Employs a worm wheel and shaft mechanism, providing high torque and self-locking capability for stable machining. While robust, this type may have some transmission gap, making it less precise and slower than direct drive models.

Clamping Methods #

- Pneumatic Rotary Table: Powered by compressed air, these tables are cost-effective and safe, offering quick start/stop for high-speed movement. Best suited for small workpieces due to limited load capacity.

- Hydraulic Rotary Table: Designed for heavy-duty applications, hydraulic systems handle large loads and allow for adjustable speed and direction. They require more complex design and technical support.

Size Options #

Rotary tables are available in a range of plate sizes to accommodate different workpiece dimensions:

- 5 inch: EDD-125AP

- 7 inch: VE-170PC

- 8 inch: FCM-200AP / FCM-200AH

- 10 inch: FCM-255AP / FCM-255AH

- 13 inch: TD-320H

- 16 inch: TD-400H

- 20 inch: TD-500H

- 25 inch: TD-630H

- 31 inch: TE-800H

- 39 inch: TD-1000H

For specialized requirements, CNC rotary tables are also available. Contact us for tailored solutions.

Featured Rotary Table Models #

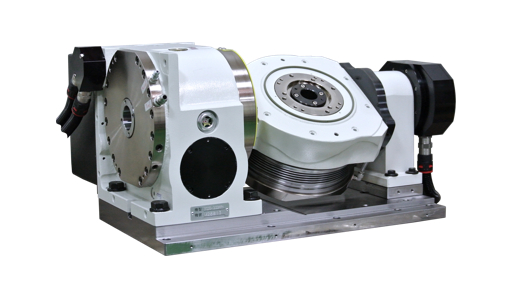

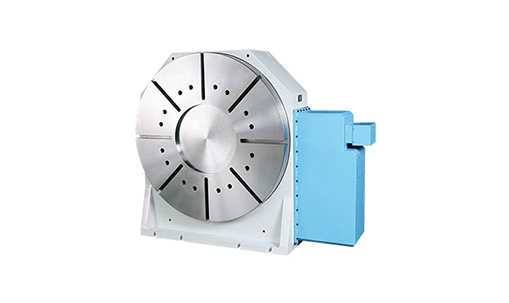

OCD5-200APH 4th Axis Rotary Table for VMC

OCD5-200APH 4th Axis Rotary Table for VMC

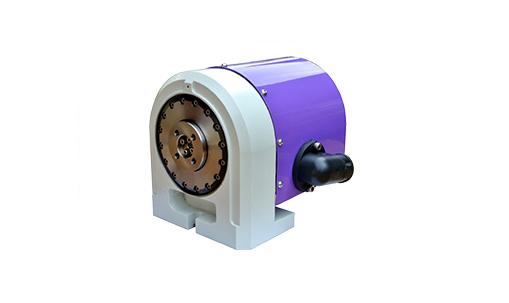

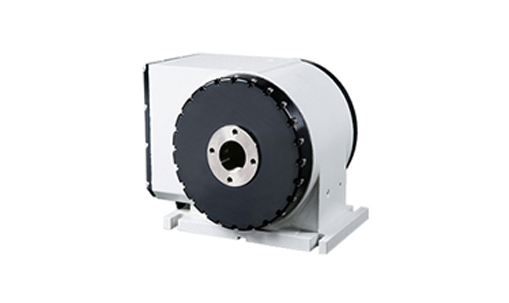

EDD-125AP Direct Drive Rotary Table

EDD-125AP Direct Drive Rotary Table

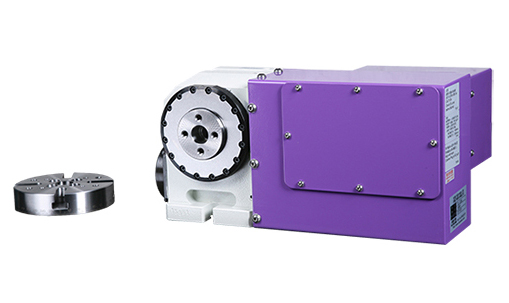

TDE-125P 5 Inch Rotary Table

TDE-125P 5 Inch Rotary Table

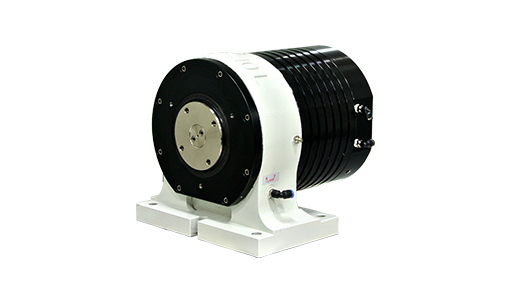

TE-125AP CNC Rotary Table

TE-125AP CNC Rotary Table

FCM-170P / FCM-170H Preload Barrel Cam Type Rotary Table

FCM-170P / FCM-170H Preload Barrel Cam Type Rotary Table

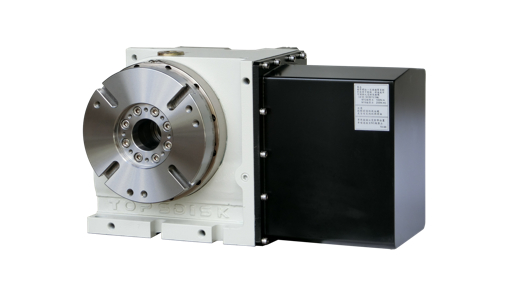

EDD-170BP Direct Drive Rotary Table

EDD-170BP Direct Drive Rotary Table

VDD-170BP Direct Drive Rotary Table

VDD-170BP Direct Drive Rotary Table

TOPSIDSK TD-170P Servo Rotary Table

TOPSIDSK TD-170P Servo Rotary Table

TD-170PL Left Hand Type NC Rotary Table

TD-170PL Left Hand Type NC Rotary Table

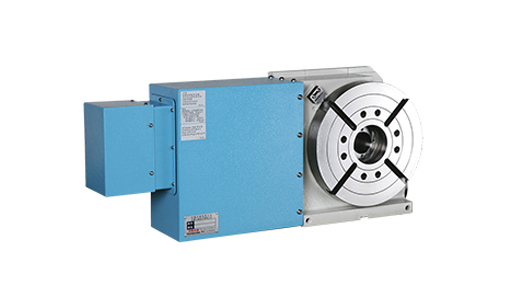

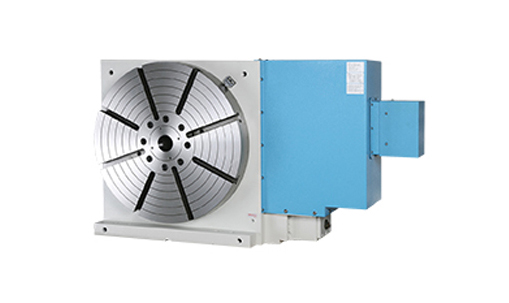

FCM-200AP / FCM-200AH Preload Barrel Cam Type Rotary Table

FCM-200AP / FCM-200AH Preload Barrel Cam Type Rotary Table

TD-200P 8 Inch Rotary Table

TD-200P 8 Inch Rotary Table

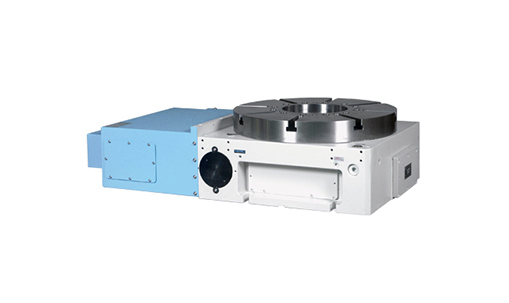

TE-200P Practical Type NC Rotary Table

TE-200P Practical Type NC Rotary Table

TE-200H NC Rotary Table (0.001°)

TE-200H NC Rotary Table (0.001°)

TDE-255H CNC Rotary Table

TDE-255H CNC Rotary Table

TD-255P CNC Rotary Table

TD-255P CNC Rotary Table

TD-255H CNC Rotary Table

TD-255H CNC Rotary Table

TE-255P NC Rotary Table

TE-255P NC Rotary Table

TE-255H CNC Rotary Table

TE-255H CNC Rotary Table

TD-255HL CNC Rotary Table

TD-255HL CNC Rotary Table

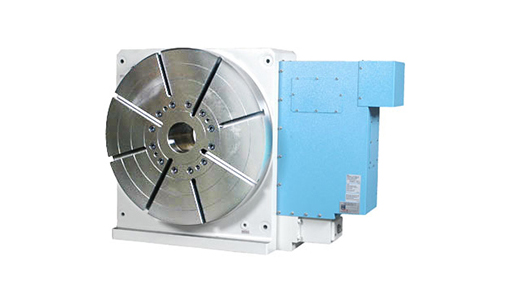

FCM-255AP/FCM-255AH Preload Barrel Cam Type Rotary Table

FCM-255AP/FCM-255AH Preload Barrel Cam Type Rotary Table

TD-320H CNC Rotary Table

TD-320H CNC Rotary Table

TD-400H CNC Rotary Table

TD-400H CNC Rotary Table

TD-500H CNC Rotary Table

TD-500H CNC Rotary Table

TD-630H CNC Rotary Table

TD-630H CNC Rotary Table

TE-800H CNC Rotary Table

TE-800H CNC Rotary Table

TD-1000H CNC Rotary Table

TD-1000H CNC Rotary Table

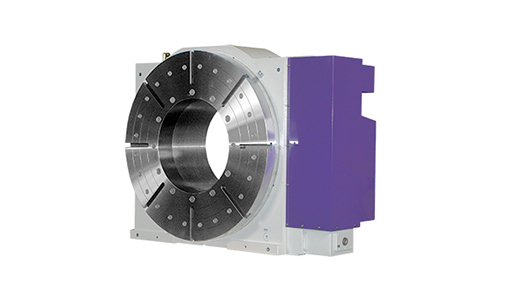

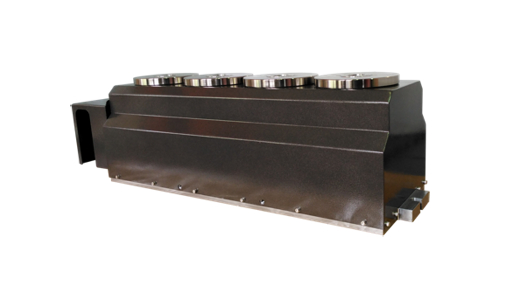

4HDD-125P Direct Drive Multi-Spindle Rotary Table

4HDD-125P Direct Drive Multi-Spindle Rotary Table

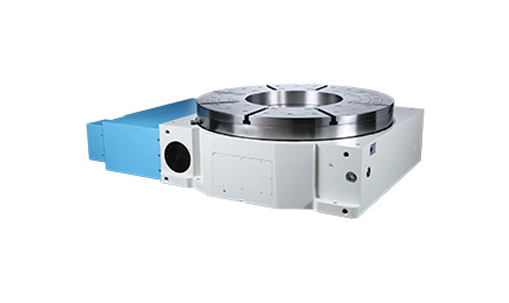

TH-500A CNC Rotary Table

TH-500A CNC Rotary Table

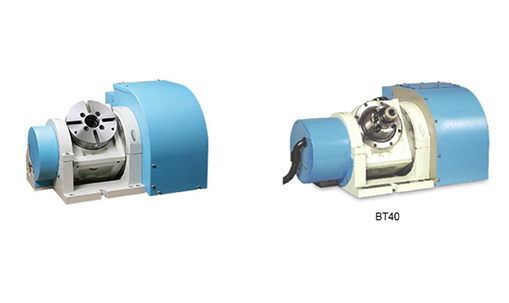

TH-500B

TH-500B

TDH-800

TDH-800

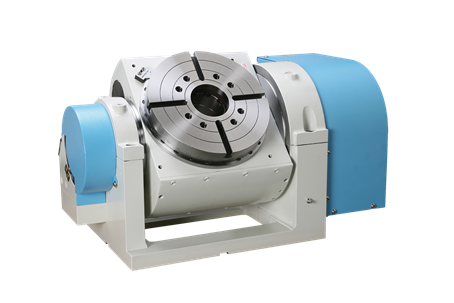

TDM-170P

TDM-170P

TDM-255HB

TDM-255HB

TTD-125P

TTD-125P

TTD-255H 5 Axis Rotary Table

TTD-255H 5 Axis Rotary Table

TTD-255HB CNC Tilting Rotary Table

TTD-255HB CNC Tilting Rotary Table

Additional Resources #

For further information or to discuss your specific requirements, please contact us.