Overview of Rotary Tables for Tool Grinding Machines #

TOPSDISK offers a specialized range of rotary tables engineered for integration with CNC and tool grinding machines. These rotary tables are available in both direct drive and worm gear configurations, supporting a variety of grinding applications and machine axes.

Product Highlights #

- Transmission Types:

- Direct Drive

- Worm Gear

- Supported Axes:

- Tool Axis (A axis)

- Grinding Head Axis

- Rotary Table for Tool Axis

- Spindle Interfaces:

- Chuck holder

- BT50 and chuck holder

- Table Types:

- Face up

- Face down

- Built-in (face up/down)

- Cooling Options:

- No cooling

- Cooling groove

- Built-in cooling circuit

- Clamp Methods:

- Pneumatic

- No brake

Featured Rotary Table Models #

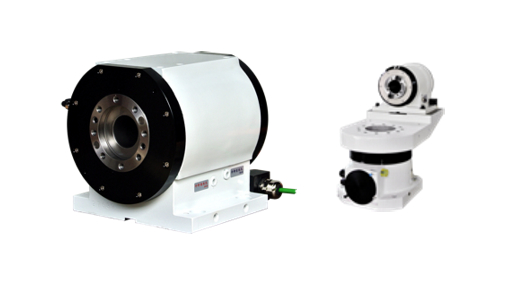

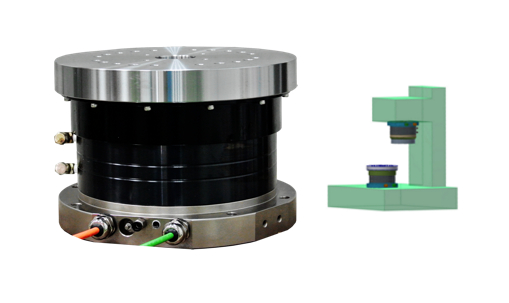

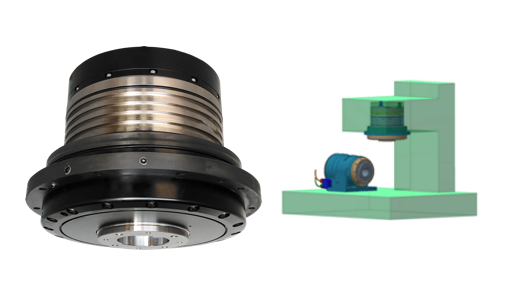

DGH-70 Rotary Table for CNC Grinding Machine (A Axis)

DGH-70 Rotary Table for CNC Grinding Machine (A Axis)

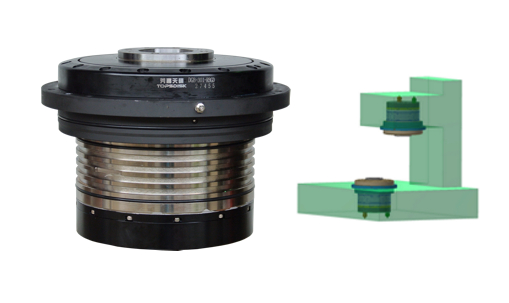

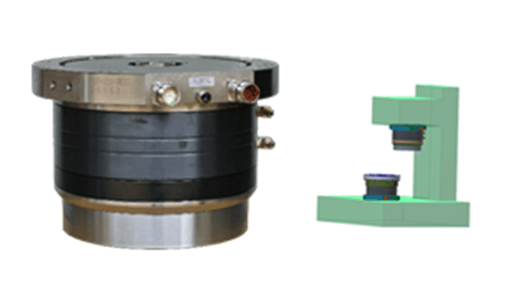

DGH-100AB5 Rotary Table specialized for Grinder

DGH-100AB5 Rotary Table specialized for Grinder

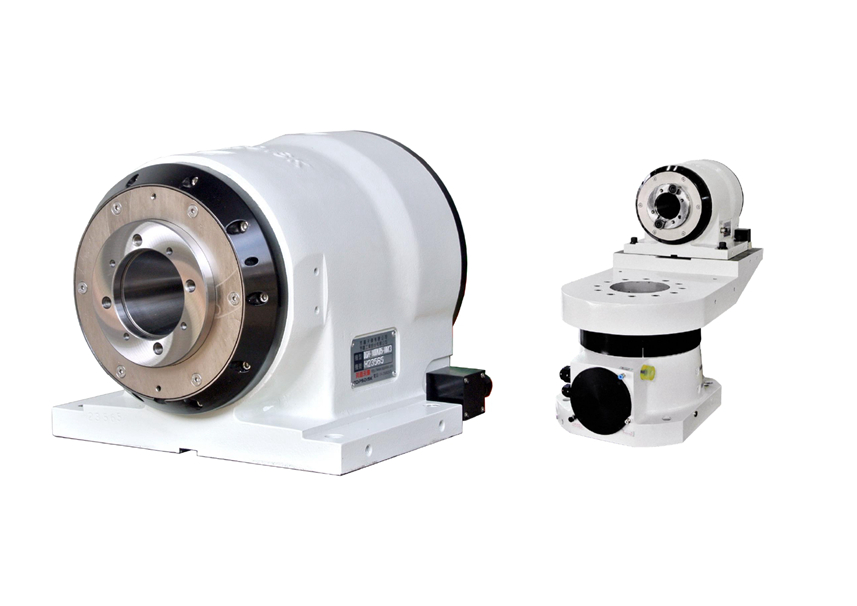

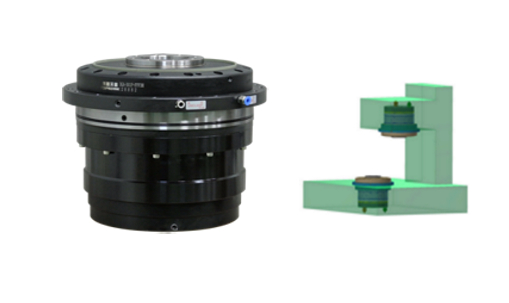

TGH-100AB5 Rotary Table Specialized for Grinders

TGH-100AB5 Rotary Table Specialized for Grinders

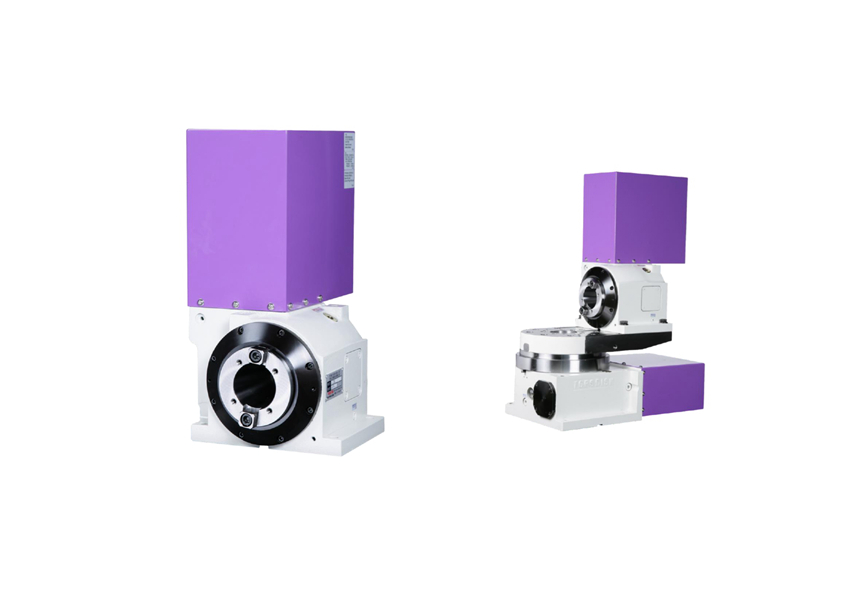

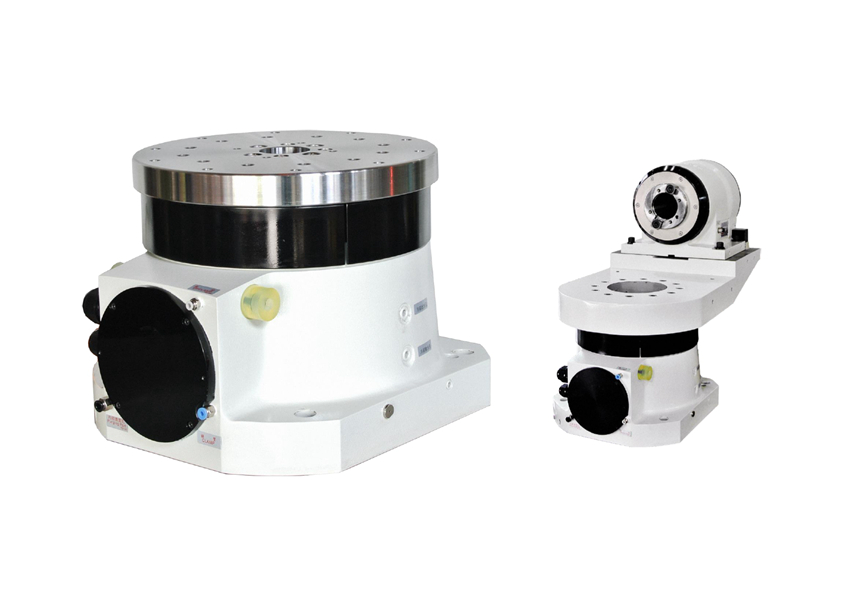

GD-255 Rotary Table for CNC Grinding Machine (C Axis)

GD-255 Rotary Table for CNC Grinding Machine (C Axis)

GD-300 Rotary Table for CNC Grinding Machine (C Axis)

GD-300 Rotary Table for CNC Grinding Machine (C Axis)

DGH-300Y / DGH-300YP Rotary Table specialized for Grinder

DGH-300Y / DGH-300YP Rotary Table specialized for Grinder

TGH-255Y Rotary Table Specialized for Grinding Machines

TGH-255Y Rotary Table Specialized for Grinding Machines

DGB-301 / DGB-301P Rotary Table for CNC Grinding Machine (C Axis)

DGB-301 / DGB-301P Rotary Table for CNC Grinding Machine (C Axis)

DGA-301 / DGA-301P Rotary Table for CNC Grinding Machine (C Axis)

DGA-301 / DGA-301P Rotary Table for CNC Grinding Machine (C Axis)

DDU-301 / DDU-301P Rotary Table for CNC Grinding Machine (C Axis)

DDU-301 / DDU-301P Rotary Table for CNC Grinding Machine (C Axis)

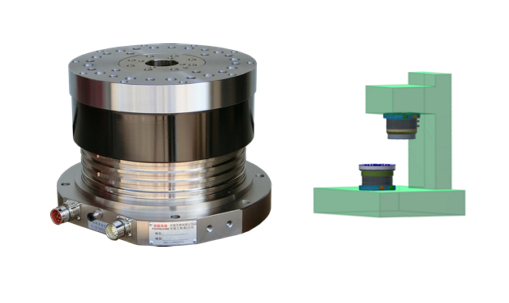

GDU-230 Rotary Table for CNC Grinding Machine (C Axis)

GDU-230 Rotary Table for CNC Grinding Machine (C Axis)

Key Features by Model #

- DGH-70: Direct drive, A axis, through hole Ø30mm, center height 120mm, spindle interface for chuck holder.

- DGH-100AB5: Direct drive, A axis, through hole Ø30mm, center height 135mm, spindle interface for BT50 and chuck holder.

- TGH-100AB5: Worm gear, A axis, through hole Ø40mm, center height 100mm, spindle interface for BT50 and chuck holder.

- GD-255: Direct drive, C axis, through hole Ø45mm.

- GD-300: Direct drive, C axis, no through hole, table type cooling circuit.

- DGH-300Y / DGH-300YP: Direct drive, C axis, through hole Ø40mm, table type cooling circuit.

- TGH-255Y: Worm gear, C axis, no through hole.

- DGB-301 / DGB-301P: Direct drive, C axis, through hole Ø40mm.

- DGA-301 / DGA-301P: Direct drive, C axis, through hole Ø70mm, built-in cooling circuit.

- DDU-301 / DDU-301P: Direct drive, C axis (grinding head), through hole Ø40mm.

- GDU-230: Direct drive, C axis (grinding head), through hole Ø40mm, table type cooling circuit.

Applications #

These rotary tables are designed for high-precision tool and CNC grinding machines, supporting both tool axis (A axis) and grinding head (C axis) operations. The variety of transmission types, spindle interfaces, and cooling options ensures compatibility with a wide range of grinding processes and machine configurations.

For more detailed specifications and application guidance, please refer to the individual product pages linked above.