Understanding CNC Lathe Tailstocks: Types, Clamping Methods, and Model Overview #

Tailstocks are essential components in lathe machines, providing critical support and stability during machining operations. At TOPSDISK, we offer a diverse range of CNC lathe tailstocks designed to meet various machining requirements. This guide presents an in-depth look at tailstock types, clamping methods, and a curated selection of our models.

Types of CNC Lathe Tailstocks #

Our CNC lathe tailstocks are categorized into two main types:

1. Center-Type Tailstocks #

Center-type tailstocks support the workpiece through a central hole, ensuring excellent stability and minimizing deformation. They are ideal for processing rotationally symmetrical workpieces such as cylinders and shafts.

2. Faceplate Tailstocks #

Faceplate tailstocks feature a large panel with multiple holes for clamping workpieces or fixtures. This design provides additional support and is particularly suited for machining larger or complex workpieces, especially in turning operations.

Clamping Methods #

Tailstocks are available with various clamping mechanisms to suit different operational needs:

- Manual Tailstock: Features a movable slide base and ratchet, with position adjusted by a handle or propeller. Simple to operate and cost-effective, suitable for general turning of various workpiece sizes and shapes.

- Pneumatic Tailstock: Utilizes compressed air for clamping, offering both automatic and manual modes. Automatic mode adjusts clamping force based on preset parameters, while manual mode allows operator control. Ideal for high-speed, efficient processing in automated mass production environments.

- Hydraulic Tailstock: Employs a hydraulic system to generate clamping force, allowing precise control by adjusting pressure. This ensures stable and accurate processing, making it suitable for high-precision parts and demanding turning applications.

Featured Tailstock Models #

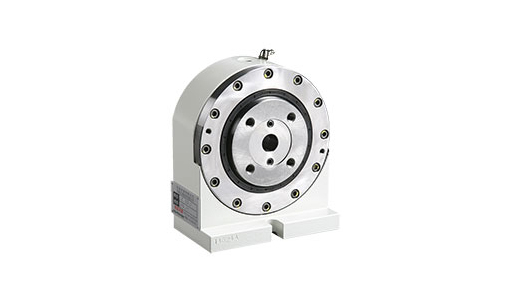

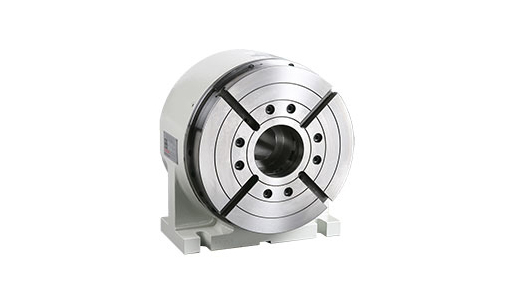

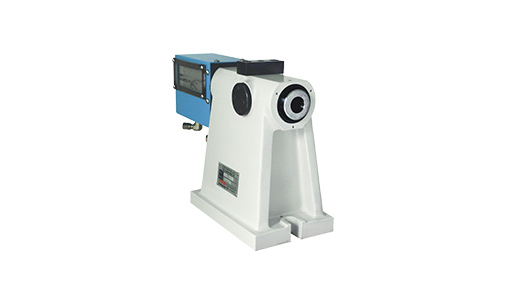

FT-110P Faceplate Tailstock

FT-110P Faceplate Tailstock

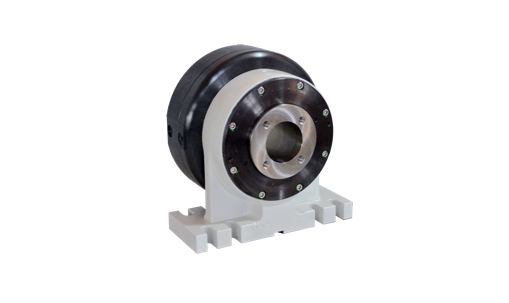

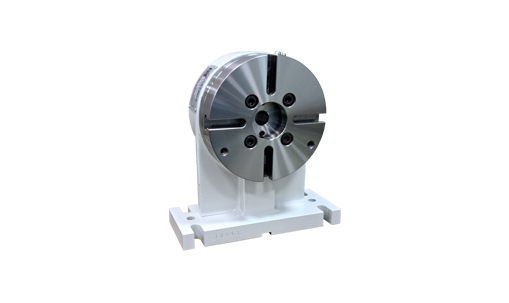

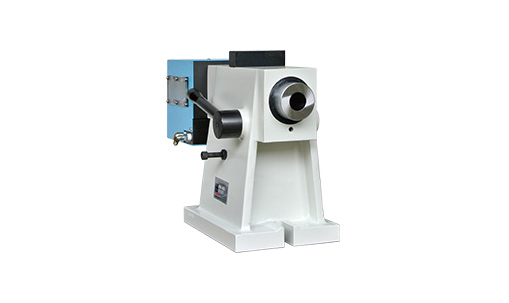

MT-110S Manual Tailstock

MT-110S Manual Tailstock

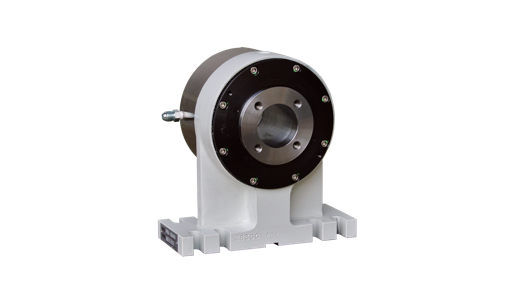

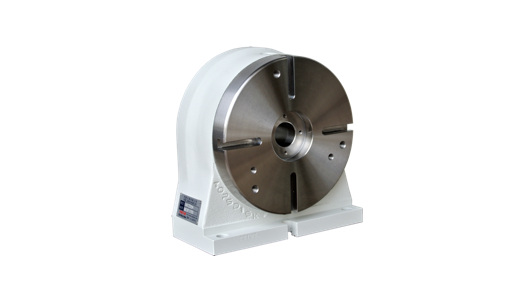

FT-135P Faceplate Tailstock

FT-135P Faceplate Tailstock

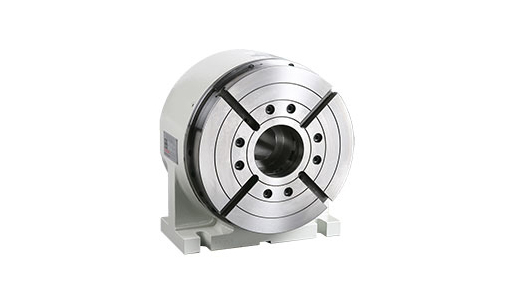

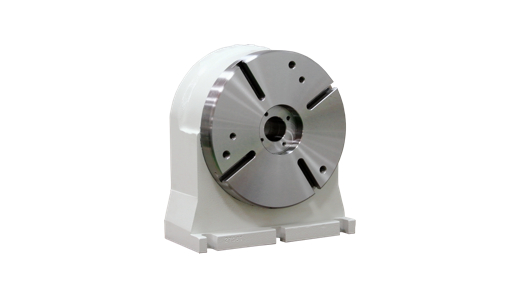

FTB-135 P/H Large Bore Faceplate Tailstock

FTB-135 P/H Large Bore Faceplate Tailstock

MT-135S Manual Tailstock

MT-135S Manual Tailstock

PTM-135S Automatic Tailstock

PTM-135S Automatic Tailstock

PTC-135S Automatic Tailstock

PTC-135S Automatic Tailstock

RT-150 NC Rotary Table Support Base

RT-150 NC Rotary Table Support Base

FT-160A P/H Faceplate Tailstock

FT-160A P/H Faceplate Tailstock

FTB-160A P/H Large Bore Faceplate Tailstock

FTB-160A P/H Large Bore Faceplate Tailstock

FT-160P Faceplate Tailstock

FT-160P Faceplate Tailstock

FT-160H Faceplate Tailstock

FT-160H Faceplate Tailstock

MT-160S Manual Tailstock

MT-160S Manual Tailstock

PTM-160S Automatic Tailstock

PTM-160S Automatic Tailstock

PTC-160S Automatic Tailstock

PTC-160S Automatic Tailstock

HTM-160S Automatic Tailstock

HTM-160S Automatic Tailstock

HTC-160S Automatic Tailstock

HTC-160S Automatic Tailstock

FT-170AP

FT-170AP

FT-170 P/H Faceplate Tailstock

FT-170 P/H Faceplate Tailstock

FT-185B P/H Faceplate Tailstock

FT-185B P/H Faceplate Tailstock

FT-210H Faceplate Tailstock

FT-210H Faceplate Tailstock

MT-210S Manual Tailstock

MT-210S Manual Tailstock

HTM-210S Automatic Tailstock

HTM-210S Automatic Tailstock

HTC-210S

HTC-210S

FT-255AH Faceplate Tailstock

FT-255AH Faceplate Tailstock

MT-255S

MT-255S

HTM-255S

HTM-255S

HTC-255S

HTC-255S

FT-310H Faceplate Tailstock

FT-310H Faceplate Tailstock

Key Specifications (Selected Models) #

- FT-110P Faceplate Tailstock: Pneumatic clamping, centre height 110mm, through hole Ø20mm, no faceplate (standard).

- MT-110S Manual Tailstock: Center replaceable type, centre height 110mm, travel 30mm.

- FT-135P Faceplate Tailstock: Pneumatic clamping, centre height 135mm, through hole Ø20mm, faceplate Ø170mm.

- FTB-135 P/H Large Bore Faceplate Tailstock: Single/double acting, pneumatic/hydraulic clamping, centre height 135mm, through hole Ø50mm.

- FT-160P Faceplate Tailstock: Pneumatic clamping, centre height 160mm, through hole Ø55mm, faceplate Ø255mm, net weight 70kg.

- FT-210H Faceplate Tailstock: Hydraulic clamping, centre height 210mm, through hole Ø40mm, faceplate Ø320mm.

- FT-310H Faceplate Tailstock: Hydraulic clamping, centre height 310mm, through hole Ø140mm, faceplate Ø500mm.

For a complete list of models and detailed specifications, please visit the Tailstock product page.

Applications #

TOPSDISK tailstocks are engineered for a wide range of machining scenarios, from general turning to high-precision and automated mass production. Whether you require manual, pneumatic, or hydraulic solutions, our tailstocks deliver reliable support and stability for your CNC lathe operations.